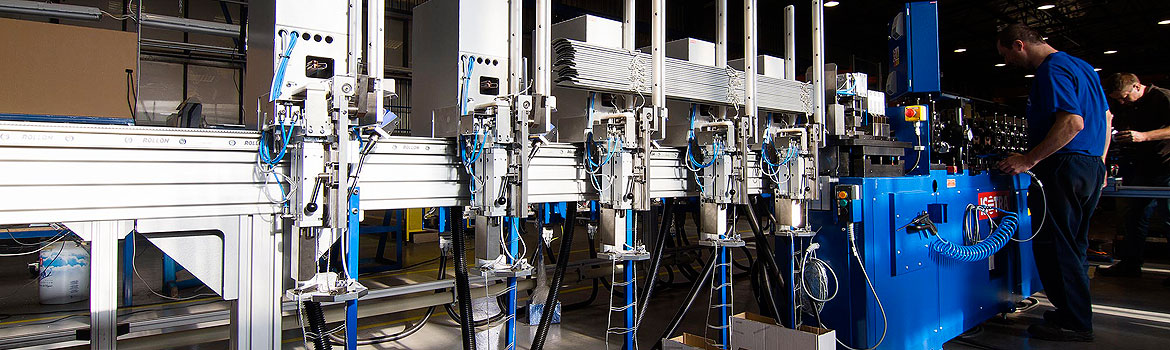

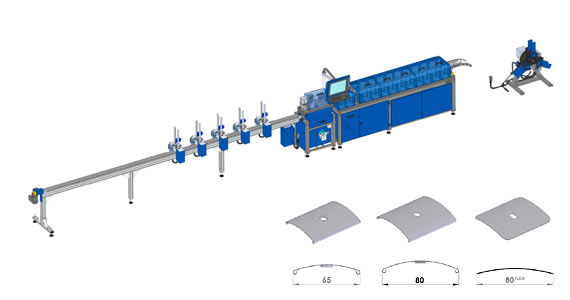

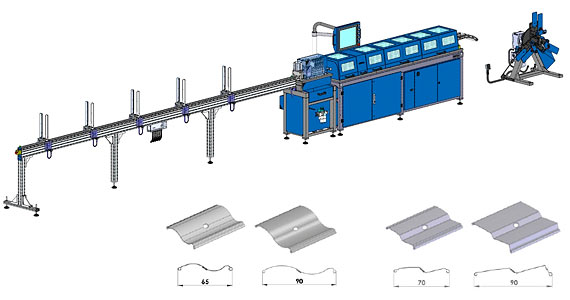

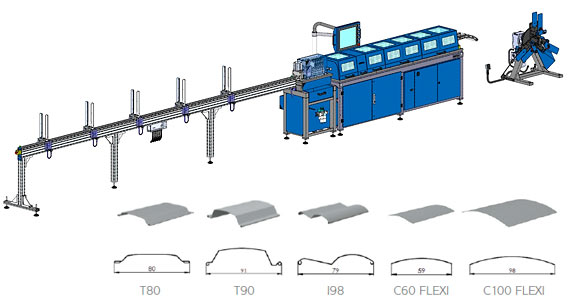

The TPL rolling mill is designed for cutting C, S, Z and T slats. The basic material to be processed is an aluminum strip. The material is shaped as it passes through the machine, after which the holes are cut into it. Thanks to the cutting trolley, which is designed for the machine, we are able to create all types of cuts, finally the cut is being cut to the desired length and put into the storage container. The drive is provided by one servomotor. Unwinding of the tape, unwinding of the rubber (S65, S90, Z70, Z90, T90) and moving the stands are provided by the additional asynchronous motors.

The rolling mill is supplied with a vibrating segment container. It automatically delivers segments (hooks) that are cut into the slats. For example, the label manipulator or inkjet used to mark the components can be installed for rolling mills, as well as a variety of tooling tools such as vibration sorting and other component installation. However, this device must be individually developed for the component. Cutting is provided by pneumatic cylindres.

Technical parameters

Technical parameters

| Max. width | 1000 mm |

|---|---|

| Max. height | 1850 mm |

| Total lenght | 12000 mm with putting off |

| Max. total weight | 2500 kg |

| Rolling speed | 1 m/s |

| Input pressure | 10 bar |

| Working pressure | 5-8 bar |

| Consumption of air pressure | 5 m3/h |

| Power voltage | 3+N+PE 400/230 V 50 Hz TN-S |

| Input power | 2,5 – 4,0 kW |

| Austic pressure | 80 dB |

Max. parameters depend on the choice of main wholes and additional equipment.

Technical parameters

Technical parameters

| Max. width | 1000 mm |

|---|---|

| Max. height | 1850 mm |

| Total lenght | 12000 mm with putting off |

| Max. total weight | 2500 kg |

| Rolling speed | Max. 1 m/s |

| Input pressure | 10 bar |

| Working pressure | 5-8 bar |

| Air consumption | 5 m3/h |

| Power voltage | 3+N+PE 400/230V 50Hz TN-S |

| Input power | 2,5 – 4,0 kW |

| Austic pressure | 80 dB |

Note.: Max. parameters depend on the choice of main wholes and additional equipment.

Technical parameters

Technical parameters

| Max. width | 1000 mm |

|---|---|

| Max. height | 1900 mm |

| Total lenght | 12000 mm with putting off |

| Max. total weight | 2500 kg |

| Rolling speed | Max. 1 m/s |

| Input pressure | 10 bar |

| Working pressure | 5-8 bar |

| Air consumption | 5 m3/h |

| Power voltage | 3+N+PE 400/230V 50Hz TN-S |

| Input power | 2,5 – 4,0 kW |

| Austic pressure | 80 dB |

Note.: Max. parameters depend on the choice of main wholes and additional equipment.

The universal pneumatic cutting machine is designed for cutting or dividing Al profiles. The basic material to be processed is aluminum slat. Cutting is performed by a mechanism operated by a pneumatic cylinder

| Max. width | 600 mm |

|---|---|

| Max. height | 1300 mm |

| Total lenght | 6500 m |

| Max. total weight | 150 kg |

| Input pressure | 10 bar |

| Working pressure | 8 bar |

| Air consumption | 1 m3/h |

| Austic pressure | 80 dB |

Note.: Max. parameters depend on the choice of main wholes and additional equipment.

It serves as a support for the installation of exterior blinds. It allows them to be manipulated - lifting and lowering with the control pedals.

| Max. width | 1 m |

|---|---|

| Max. height | 6 m |

| Total lenght arm | 3 m |

| Total weight | 600 kg |

| Max. lifting capacity | 100 kg |

| Max. moment load | 120 Nm |

| Power voltage | 240 V |

| Input power | 400 W |

| Noise level | up to 60 dB |

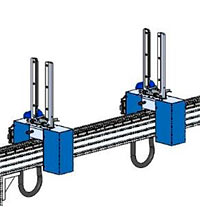

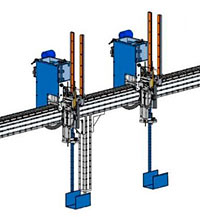

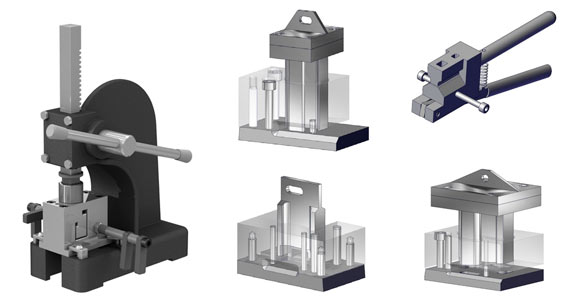

Slat perforation, manual profiles cutting, interchangeable cutting blocks for all types of machines.